Packing consists of appropriate placement and distribution of the goods inside of a cargo transport unit (CTU) (shipping container, lorry trailer, etc.), while securing or attachment is the set of techniques used to prevent shifting of the goods during shipping. Both of these processes depend upon factors such as the characteristics of the transport unit, the shape and weight of the goods, and their packages or containers, among others.

Packing

PACKING AND SECURING OF CARGO

Packing consists of appropriate placement and distribution of the goods inside of a cargo transport unit (CTU) (shipping container, lorry trailer, etc.), while securing or attachment is the set of techniques used to prevent shifting of the goods during shipping. Both of these processes depend upon factors such as the characteristics of the transport unit, the shape and weight of the goods, and their packages or containers, among others.

Who is responsible?

The shipper is responsible for preparing the goods in packages or containers appropriate for the mode of transport and for the vehicle that will be used.

The shipper is also responsible for adequately packing and securing the cargo, except in operations where the logistical operator has been expressly contracted to do this.

LEGISLATION AND STANDARDS

The responsibilities related to packing and securing are defined in the legislation related to domestic and international transport of goods. Law on the Contract for Overland Transport, CMR Convention,OTIF Convention, and Hague Visby Rules, among others.

There are certain special types of goods where packaging, containers, packing, and securing are regulated at an international level. Dangerous goods are subject to the IMDG Code for maritime shipping, the ADR Convention for road transport, the RID Convention for railway transport, and theIATA DGR Rules for air cargo.

There are also guidelines and recommendations for packing and securing general cargo, although these do not always involve legislation that has been standardised internationally. The most important reference is the CTU Code, produced by a group of experts from the International Maritime Organization (IMO), the International Labour Organization (ILO), and the United Nations Economic Commission for Europe (UNECE). It is also possible to consult specialised sources, such as Estiba y trincaje de mercancías en contenedor in Spanish or manuals produced by associations in the transport industry, such as theIRU Manual.

SHIPPING INSURANCE

Domestic and international insurance policies that cover shipment of goods have exclusion clauses related to inadequate or insufficient packing and packaging.

If an accident occurs and the expert or damage committee determines that inappropriate packing or packaging was the cause, the insurance company will refuse to compensate the company whose goods were being shipped. This company will then become solely liable for the damages produced to its goods as well as for any damages caused to third parties (for example, damage to the shipping container or transport vehicle).

RECOMMENDATIONS

Packing of goods according to their physical properties: if the strength of the containers allows it, liquid goods should be loaded beneath solid goods. This way any leaking liquid will end up on the floor rather than damaging the rest of the cargo. It is also good practice to put lightweight cargo on top of heavy cargo in order to prevent damage by crushing.

Segregation of incompatible goods: goods that are considered incompatible cannot be shipped together in the same cargo transport unit (CTU), such as certain chemical products, foods together with toxic products, etc.

Uniform distribution of pressure on the packages: when stacking, the pressure exerted on packages by other packages must be considered. If necessary, rigid panels should be placed between stacks in order to adequately distribute the pressure on the cargo.

Securing the cargo: goods must not be allowed to move around inside of the CTU, with the acceleration factors for each transport mode being taken into account. This means that goods must be tied down, propped up, or blocked into place as necessary, using approved and certified filler materials.

Prevention of excessive handling: It is a good idea to plan for partial unloading of cargo to avoid the need to reload goods, since in addition to causing excess costs, this increases the risk of damage to them. For example, if a container is loaded with some pallets for destination A and some others for destination B and they must be delivered in that order, locating the cargo to be unloaded first near the door will make unloading quicker and only the goods necessary will need to be handled.

Professional training and occupational risk prevention: the operating personnel must have the required training on cargo handling and must make use of protective equipment that is appropriate in view of the characteristics of the goods they will have to handle.

Risk prevention when handling goods: the means of manipulation used for handling the goods must be chosen with special attention given to the conditions of stability inside of the CTU. For example, in the case of a container being moved from a loading dock onto a lorry’s trailer, the lorry’s cab must remain attached with the brakes applied at all times. If the trailer is detached, proper supports must be placed under the rear part to prevent an accident that could otherwise be caused by the trailer tipping when the forklift enters the container.

Risk prevention when handling the CTU: it is essential to observe the hazard warnings that appear on the door of the CTU in order to ensure the safety of the personnel manipulating it. For example, if a container is transporting a bulk liquid using a flexible tank, only the right-hand door must be opened, with the left-hand door remaining closed until the tank has been fully emptied. Caution must also be exercised to ensure that any goods located in the area adjacent to the door do not fall onto the person responsible for opening the CTU. This means that the cargo must be secured using tie-down nets or other alternative attachment elements that can contain the weight of the goods.

Uniform distribution of the cargo: the goods must be uniformly distributed in the CTU. Concentrating too much cargo in a small area must be avoided. However, if this becomes necessary, appropriate beams or supports must be used to distribute the weight in a uniform manner across the entire floor surface.

Establishing the cargo’s centre of gravity: the longitudinal centre of gravity for the cargo must be adjusted to the cargo diagram recommended for the CTU. For example, in the case of a container it must coincide with its geometric centre. The cargo’s transverse centre of gravity must also coincide as closely as possible with the geometric centre of the CTU running in the same direction. This centre of gravity should also be as low as possible, and in no case should it be located at more than half of the CTU’s height.

CONTAINERS

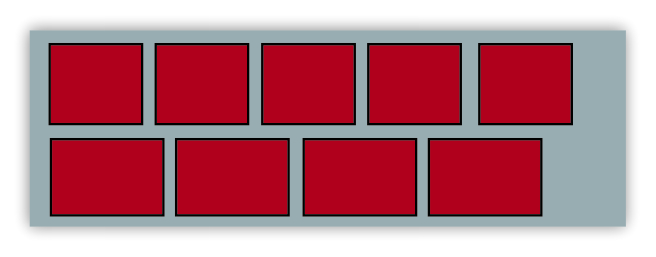

STUFFING PLAN

To avoid problems such as cargo overflow or wastage of space, it is essential for shippers to have a stuffing plan before cargo is loaded into the container.

20′ Container

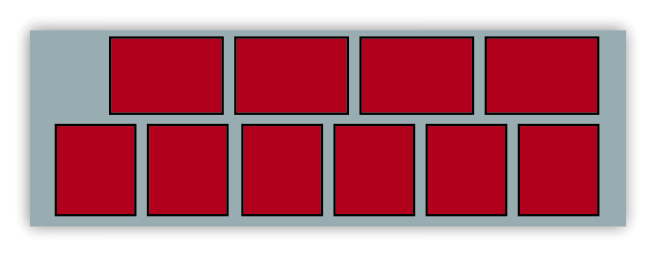

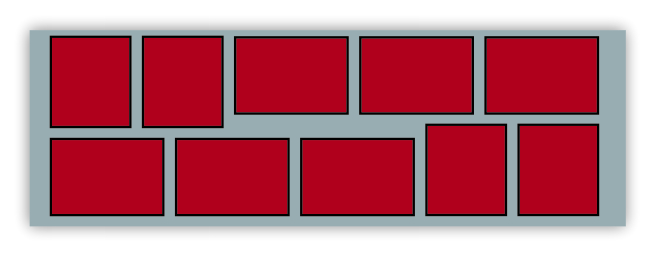

9 standar pallets 1000 x 1200

10 standar pallets 1000 x 1200

11 europallets 800 x 1200.

MEASUREMENT

Generally speaking, a 20′ container can hold as much as 28-30 cbm or 980-1,060 cu.ft., while a 40′ can hold about 56-60 cbm or 1,980-2,110 cu.ft. The actual loading Internal Capacity of a container depends not only on the dimensions of the carton boxes but also on many other factors such as the packaging material and the competence and experience of the stuffing personnel.

40′ container

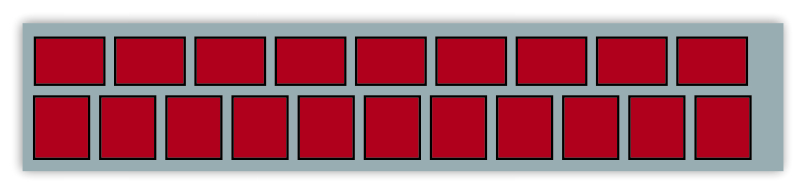

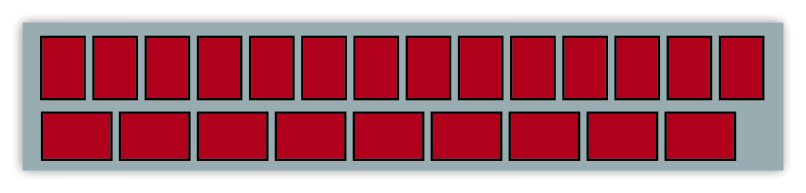

20 standard pallets 1000 x 1200

21 standard pallets 1000 x 1200

23 europallets 800 x 1200

24 europallets 800 x 1200

WEIGHT

Besides the cargo’s measurement, the stuffing plan should also take the weight into consideration. It is important to note that in many countries the permissible weight limits for road and rail transportation are lower than the maximum payload a container can afford.

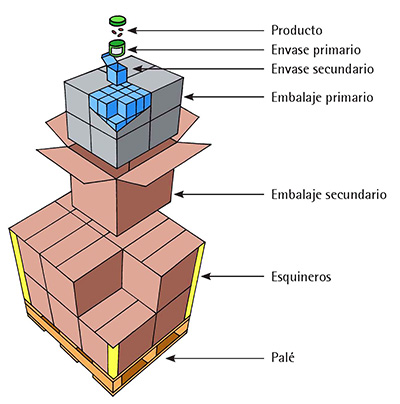

USE OF PALLETS

Palletization is widely applied in some countries to increase cargo handling efficiency. When pallets are used, it is important to observe that :

There are two major types of pallets, “Europallet” and standard pallets. The size of the “Europallets” is 800mm x 1,200mm per piece while the size of standard pallets is 1,000mm x 1,200mm per piece.

A 20′ container can hold eleven “Europallets” in one tier or nine to ten standard pallets in one tier while a 40′ container can hold 23-24 “Europallets” in one tier or 20-21 standard pallets in one tier.

Wooden pallets must be strong enough to allow storage of three tiers when loaded.

Carton boxes must not overhang the edges of the pallets. On the other hand, boxes which utilize less than 90% of the pallet surface and do not align with the pallet edge can shift in transit.

In many cases, pallets are replaced by slipsheets to save space. some shippers use neither pallets or slipsheets in order to stuff more cargo into the container.